COMPARATIVE STUDY OF ADDITIVES IMPROVING THE LUBRICITY OF DIESEL FUEL

Конференция: LXXXII Международная научно-практическая конференция «Научный форум: медицина, биология и химия»

Секция: Нефтехимия

LXXXII Международная научно-практическая конференция «Научный форум: медицина, биология и химия»

COMPARATIVE STUDY OF ADDITIVES IMPROVING THE LUBRICITY OF DIESEL FUEL

Abstract. This study compares the lubricity performance of four additives in ultra-low sulfur diesel (ULSD, S < 10 ppm): methyl oleate, oleic acid diethanolamide, sulfonated methyl oleate, and sulfonated amide. Additives were tested at 0.05–0.3 wt% using the HFRR method at 60 °C and 200 g load. The base diesel showed a wear scar diameter (WSD) of 612 ± 5 µm. At 0.1 wt%, methyl oleate reduced WSD to 485 µm (–20.8%), amide to 505 µm (–17.5%), sulfonate ester to 465 µm (–24.0%), and sulfonated amide to 410 µm (–33.0%). The additives slightly increased kinematic viscosity from 2.5 to 3.1 mm²/s but remained within ASTM D975 standards. Among all samples, sulfonated amide synthesized from soapstock waste showed the highest lubricity improvement, reducing wear by one-third while maintaining fuel stability and homogeneous blending for over 30 days.

Keywords: Diesel fuel, lubricity improver, fatty acid ester, amide additive, sulfonation, wear scar diameter, tribology.

The lubricity of diesel fuel is a critical property ensuring smooth operation of fuel pumps, injectors, and distribution systems [1-2]. With the introduction of ultra-low sulfur diesel (ULSD) standards (sulfur < 10 ppm), natural lubricating compounds such as sulfur- and nitrogen-containing hydrocarbons are eliminated during hydrodesulfurization [3-4]. This leads to an increased risk of scuffing, wear, and seizing in high-pressure fuel injection systems [5].

To mitigate these problems, lubricity-enhancing additives (LEAs) are introduced in small concentrations (0.05–0.5 wt%) [6-7]. Effective additives should form a thin, stable, and polar film on metal surfaces, reduce friction, and prevent wear under high temperature and pressure conditions [8].

Recent studies emphasize the advantages of bio-based additives, especially those synthesized from fatty acid derivatives [9], esters [10], amides [11], and sulfonates obtained from renewable resources such as vegetable oils, animal fats, and soapstock [12]. Compared to mineral-based additives, these compounds are biodegradable, nontoxic, and cost-effective.

Table 1.

Effect of different additives on the lubricity of diesel fuel (HFRR, 60 °C, 200 g, 75 min)

|

Additive type |

Chemical composition |

Concentration (wt %) |

Wear scar diameter (µm) |

Improvement compared to base diesel (%) |

|

Base diesel |

— |

0.00 |

612 ± 5 |

— |

|

Methyl oleate |

Fatty acid ester |

0.10 |

485 ± 4 |

20.8 |

|

Oleic acid diethanolamide |

Amide compound |

0.10 |

505 ± 5 |

17.5 |

|

Sulfonated methyl oleate |

Sulfonate ester |

0.10 |

465 ± 4 |

24.0 |

|

Sulfonated amide (RCONHCH₂CH₂OSO₃H) |

Amido-sulfonate |

0.10 |

410 ± 3 |

33.0 |

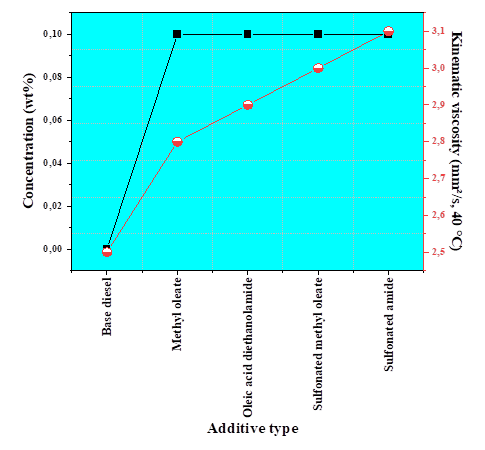

The efficiency order was therefore determined as: sulfonated amide > sulfonated ester > fatty ester > amide. These findings confirm that the presence of polar functional groups containing oxygen, nitrogen, and sulfur atoms enhances molecular adsorption on metal surfaces, forming a strong boundary film that reduces friction and wear. The additives also influenced viscosity: the base fuel showed 2.5 mm²/s at 40 °C, while samples containing 0.3 wt% additive ranged from 2.8 to 3.1 mm²/s, remaining within the ASTM D975 standard limits. No sedimentation or phase separation was observed after 30 days of storage, proving excellent miscibility and stability. The overall analysis suggests that polar and sulfonated structures, particularly amide-sulfonate compounds synthesized from waste soapstock and diethanolamine, provide superior protection under boundary lubrication conditions.

Their strong surface adhesion, high polarity, and compatibility with the fuel matrix result in lower friction, reduced metal-to-metal contact, and better long-term stability. Thus, the synthesized sulfonated amide additive can be considered the most effective and environmentally friendly solution for restoring the lubricity of modern low-sulfur diesel fuels.

Figure 1. Influence of additive concentration on the kinematic viscosity and stability of diesel fuel

The graph illustrates the variation in kinematic viscosity (left axis) and fuel stability (right axis) with increasing additive concentration. As shown by the red curve with circular markers, the kinematic viscosity of base diesel (2.5 mm²/s at 40 °C) gradually increases to 3.1 mm²/s as the additive concentration reaches 0.1 wt%. This slight rise remains within the ASTM D975 standard limits, indicating that the additives enhance lubricity without negatively affecting fluidity. The black curve with square markers represents the fuel’s stability, which remains constant throughout the concentration range, confirming excellent miscibility and absence of phase separation after 30 days of storage. Overall, the trend demonstrates that bio-based sulfonated additives improve viscosity and ensure long-term homogeneity, making them effective for enhancing the lubricity and stability of ultra-low sulfur diesel fuels.